CMOS mixed-signal conditioning chip (including adjustable PGA and 24-bit Σ-Δ ADC) amplifies, calibrates and compensates the output of the MEMS core, and can convert the signals of different pressure ranges from - 10kPa to+10kPa and - 350kPa to+350kPa into analog signals and digital I2C signals with user-defined output range (0~5V). At the same time, the built-in MEMS differential pressure core is designed based on the high sensitivity single crystal silicon piezoresistance effect and the advanced silicon silicon bonding CSOI MEMS micromachining process. The accuracy and stability of the MEMS core in its life cycle is better than 1% F.S.

The main features of the product are as follows:

High accuracy and low power consumption: high linearity, good stability, no need for calibration, 100% temperature compensation, ex-factory accuracy better than ± 1% F.S., accuracy better than ± 2% F.S. in the life cycle.

Multiple output modes: support analog absolute output and digital I2C output, suitable for various application requirements, simple and convenient, and good portability.

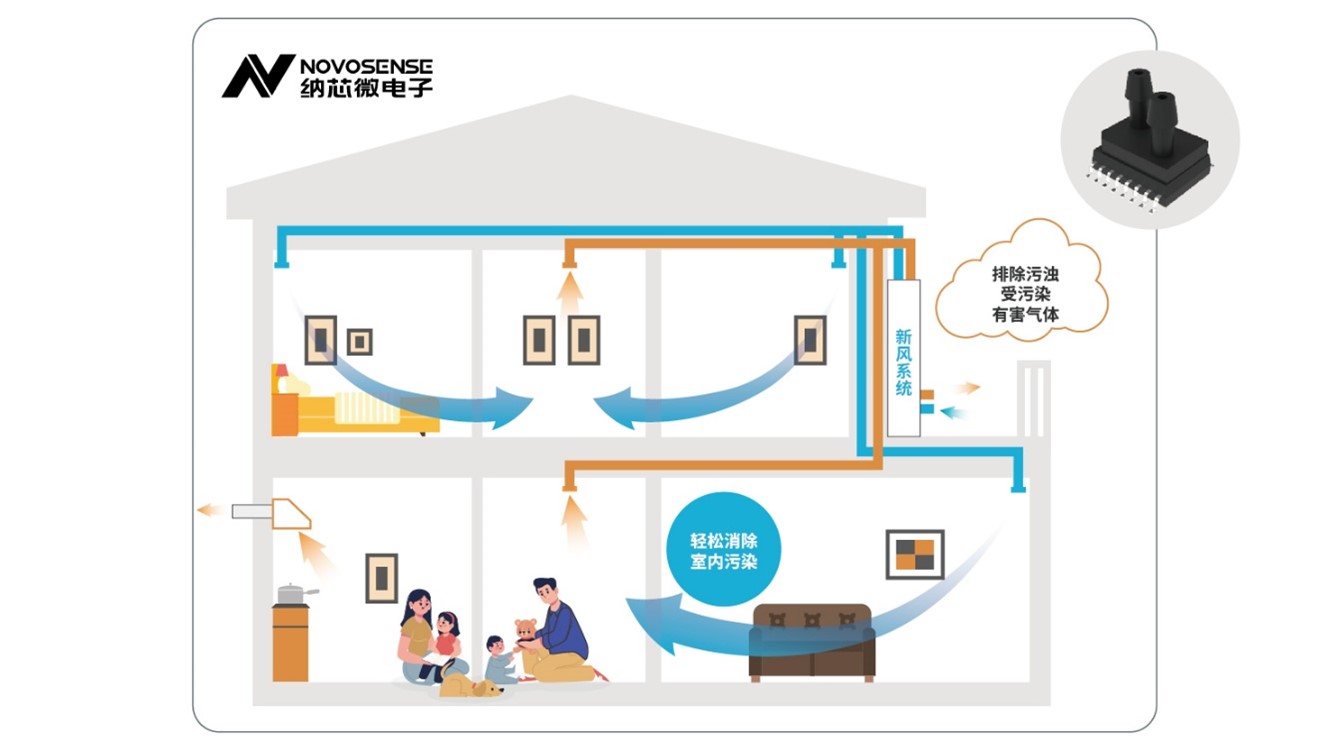

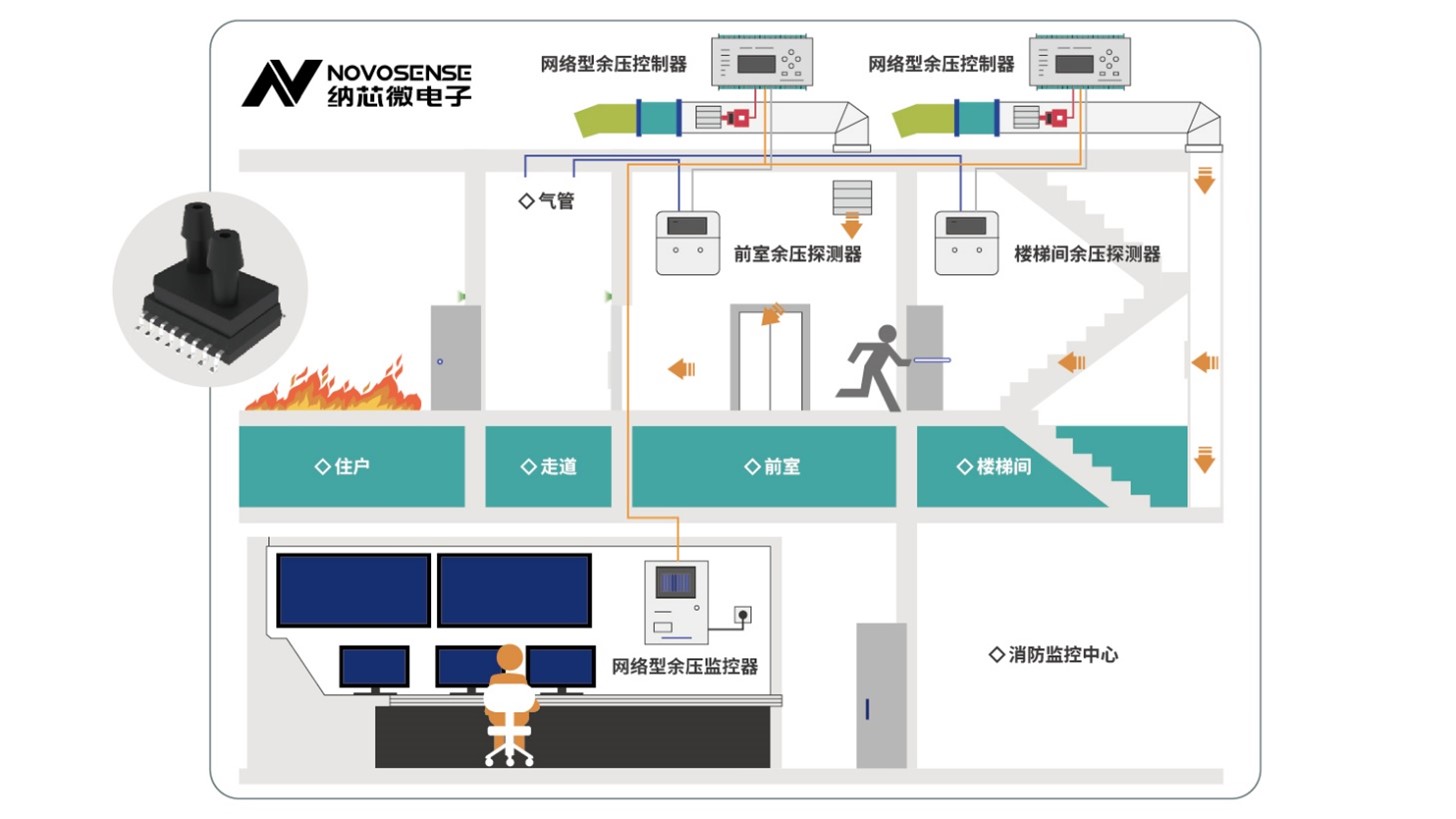

Customized products: support the customization of multiple ranges such as - 10kPa~+10kPa and - 350kPa~+350kPa, which are applicable to a variety of pressure application scenarios with high flexibility.

Wide temperature range: - 20 ℃~70 ℃ working temperature, suitable for all kinds of harsh working environment; At the same time, the temperature compensation range of 0 ℃~70 ℃ can reduce the impact of temperature change on product performance and ensure product stability.

Packaging form of double air nozzles: adopt the packaging form of double air nozzles SOIC-16 in line with the industry JEDEC standard, which can be pin-to-pin compatible with SMI micro-differential pressure series products; With high reliability and stress relief characteristics, it is convenient for customers to weld and use while ensuring excellent performance and reliability of products.

Nano-core micro not only has the independently developed MEMS design and packaging technology, as well as the automatic batch calibration technology of multiple pressure and temperature points; It can provide customers with more flexible delivery and reduce supply chain risks; It can also provide customized sealing products according to customer needs to meet the application requirements of different scenarios.