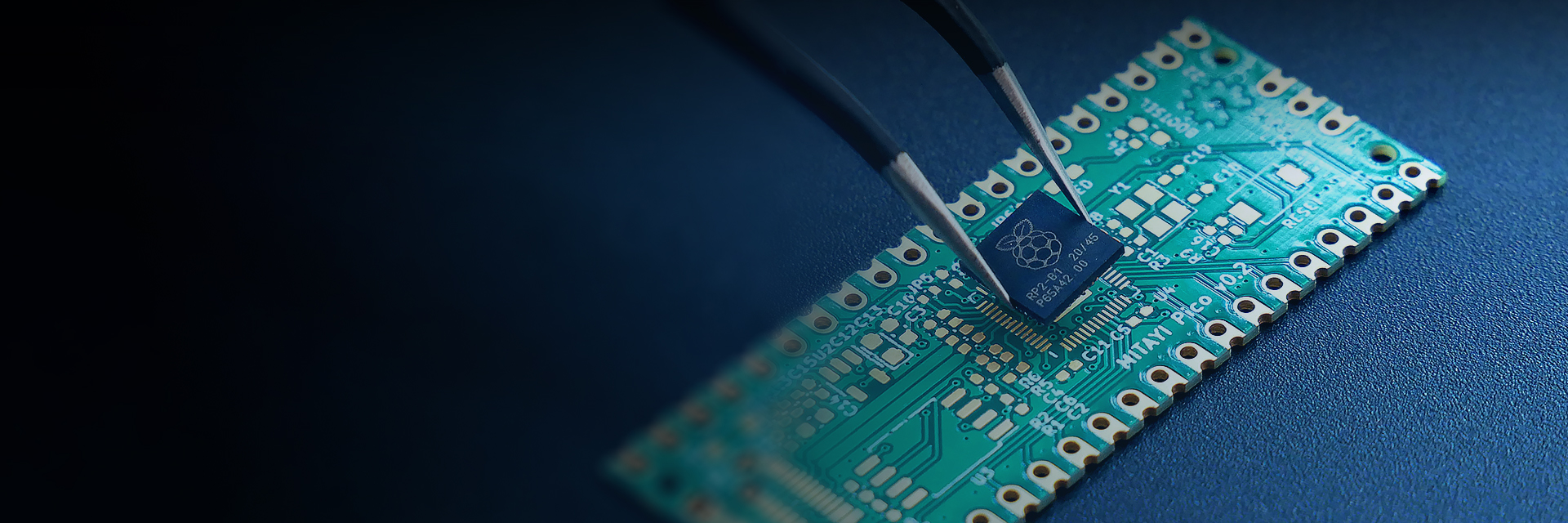

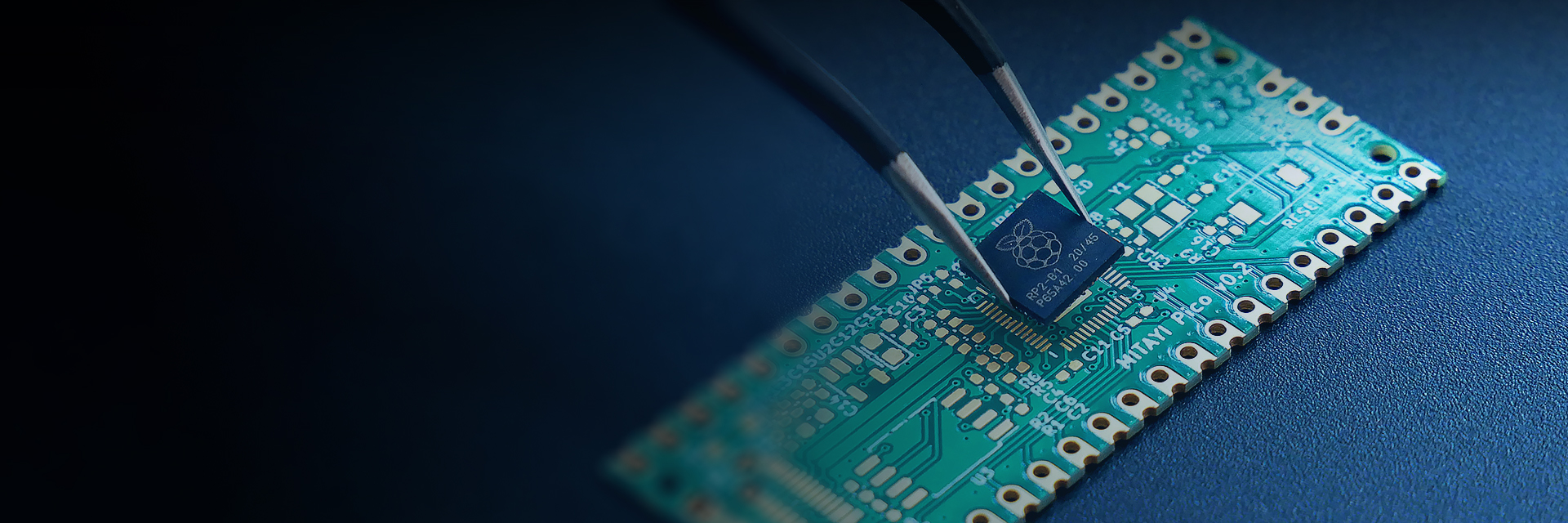

Authoritative quality certification

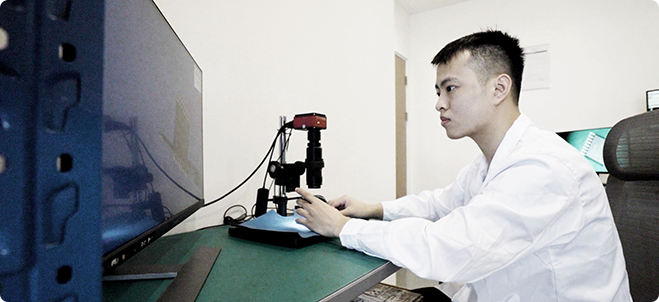

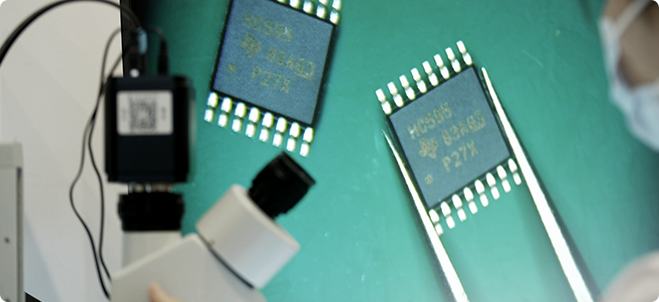

HJC is dedicated to exceed customer requirements and expectations, adhere to third-party certification requirements, while constantly improving our quality management system, so as to provide customers with the highest level of products and services.